Identifying Worm Gear Defects

With a reputation for running smoothly and quietly, worm gears are used in a variety of applications including small engines, presses, lifts, elevators, rolling mills, conveying engineering, mining industry machines, on rudders, and worm drive saws.

With a reputation for running smoothly and quietly, worm gears are used in a variety of applications including small engines, presses, lifts, elevators, rolling mills, conveying engineering, mining industry machines, on rudders, and worm drive saws.

Compared to standard gears, a worm gear can have a substantial reduction ratio with little effort. Another advantage is the inability to reverse the direction of power. Finally, on a standard gear, the input and output can be turned independently. This requires adding a backstop to a standard gearbox, further increasing the complication of the gear set.

Noise Issues

For one leading manufacturer, and Signalysis customer, a change in worm gear suppliers resulted in the manufacturing of product with ticking noise. Mid-week the manufacturer was alerted to the sound issue and told to contain this problem.

For one leading manufacturer, and Signalysis customer, a change in worm gear suppliers resulted in the manufacturing of product with ticking noise. Mid-week the manufacturer was alerted to the sound issue and told to contain this problem.

To compound the situation the company was told that a verification inspection will be performed two days later. The manufacturer called Signalysis for assistance and transferred several sets of data.

Unmatched Responsiveness

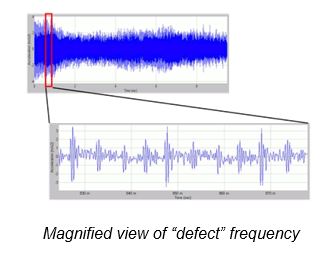

Signalysis engineers analyzed the data and developed a metric in less than 4 hours. The day before verification, Signalysis used the Internet to login and implement the new tick metric.

Normal production was started to create a statistical population of the good product. The customer reject was used to establish a defect limit. By mid-morning the customer was able to begin preparing for inspection and avoid costly containment.