Automotive HVAC

Automated Quality Testing of Automotive HVAC Units

Heating, Ventilation, and Cooling systems are vital to today’s driving experience. With customer satisfaction tested with each push of a button, noise, vibration, and failure are not an option.

Challenge

Challenge

Develop a functional test system that cycles HVAC assemblies through all of their functions to validate quality.

Calling the Experts

The customer, a Tier 1 automotive supplier, called upon Signalysis to develop an automated quality test system capable of evaluating 100% of the manufactured units.

Testing Goals:

- Provide inspection for all manufactured HVAC units

- Meet cycle time requirements

- Store data in an SQL database by SN and time/date

- Provide daily production reports

- Serve Data for Statistical Process Control

Blowing away NVH Issues

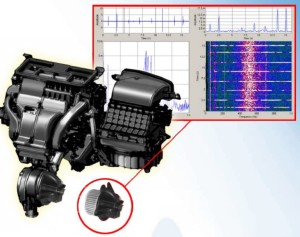

Signalysis designed and developed a custom IQC™ test station providing the customer with the ability to:

- Equate subjective assessments to root cause

- Validate aesthetic & functional specifications

- Minimize production cycle time impact

- Eliminate the cost & subjectivity of human inspection

The IQC station included:

- A computer control system

- Multi-channel data acquisition system

- Digital I/O interface hardware

- Accelerometers / automated placement devices

- SigQC™ analysis software

Results

Tests on each HVAC unit were conducted to detect defects in sound quality and functional specifications including: current, rpm, pressure, louver arc, and so on.

As a result of implementing the Signalysis IQC Test System, all test requirements were met. As a result, the manufacturer could proceed confident that its own rigid quality standards, and lofty expectations of its customers, were not only met; but exceeded.